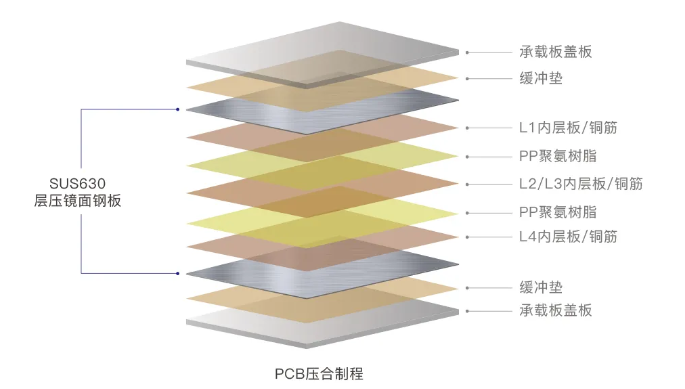

Shocking developments in the PCB and CCL industries: Who is the real dark horse among the best materials?

With the rapid development of technology, the demand for electronic products is constantly increasing. In the fields of CCL (Copper Clad Laminate) and PCB (Printed Circuit Board), the selection of materials is of utmost importance.

SUS630 laminated mirror steel plates meet the required specifications regarding high hardness, roughness, surface accuracy, and thermal expansion coefficient, making them an essential component in the production of high-quality electronic products.

In the fields of PCBs and CCLs, it is particularly important to prevent corrosion from having a negative impact on the performance of circuit boards and cover laminates. The corrosion resistance of SUS630 enables it to maintain the integrity and performance of the material in humid environments, in contact with chemicals, and in acidic or alkaline solutions, thus ensuring that circuit boards and cover laminates can operate stably for extended periods of time.

As core components of electronic products, PCBs and CCLs must possess sufficient strength and hardness to withstand physical impacts and vibrations. After undergoing solution treatment and aging treatment, SUS630 laminated mirror steel plates can achieve high strength and hardness, thereby ensuring the reliability and stability of both the circuit boards and the covering laminates. These materials are capable of withstanding the pressures and vibrations present in various external environments, ensuring that electronic products function properly under all operating conditions.

Following the aging treatment process, the yield strength of SUS630 laminated mirror steel plates can exceed 1300 MPa, their tensile strength can reach around 1500 MPa, and their hardness can go above HRC47.

Circuit boards and cover laminates may be subjected to friction and repeated cyclic stresses during use. SUS630 laminated mirror-finished steel plates possess excellent wear resistance and fatigue resistance, enabling them to withstand prolonged friction and repeated impacts. As a result, circuit boards and cover laminates can maintain a long service life and stable performance even under conditions of high-speed operation, frequent connection and disconnection.

Methods such as ball wear testing and fatigue testing have demonstrated that these materials have a low wear rate and an excellent fatigue life, allowing them to perform exceptionally well under high-speed operation and frequent stress.

SUS630 possesses excellent adjustability, allowing its properties to be modified during the heat treatment process. This enables manufacturers of PCBs and CCLs to carry out heat treatment according to specific requirements, ensuring that these materials are suitable for various application scenarios and operating conditions. The adjustability of the material ensures that electronic products can perform optimally in different environments, thus extending their service life.

As a high-quality material, SUS630 holds great potential in the fields of PCBs and CCLs. Its outstanding corrosion resistance, high strength and hardness, wear resistance, fatigue resistance, as well as its adjustability and heat treatment properties, make it an ideal choice for manufacturing high-quality electronic products. By using SUS630, the reliability, stability, and durability of electronic products can be improved, meeting consumers' demands for high-quality products and contributing to the sustainable development of the electronics industry.