The way of steel: striving for excellence! Producing high-quality pressed steel plates!

With the increasing refinement of the line width and pitch of printed circuit boards, as well as their multi-layer structure; and the gradual thinning of the copper foil used in these boards, the use of inner chips in credit cards has become more widespread. Our company has established an advanced production line specifically designed for the grinding of PCBs and CCLs. This production line consists of two stages: rough grinding and polishing, to ensure that the final products meet the strict requirements regarding high hardness, surface roughness, dimensional accuracy, and thermal expansion coefficient.

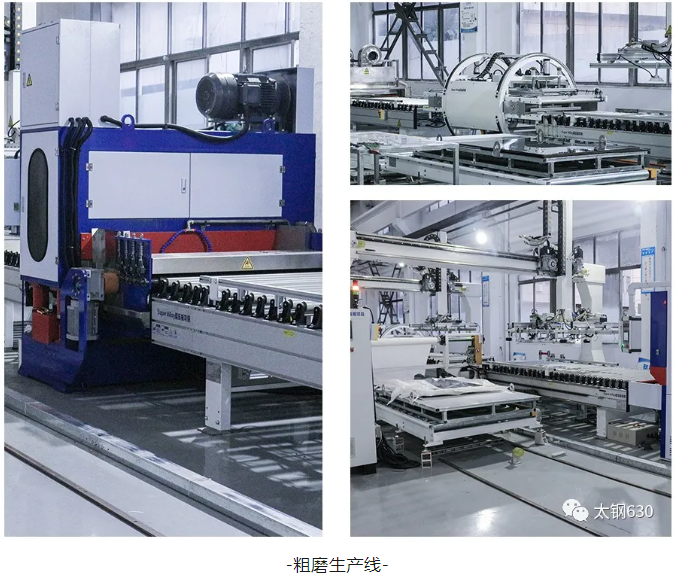

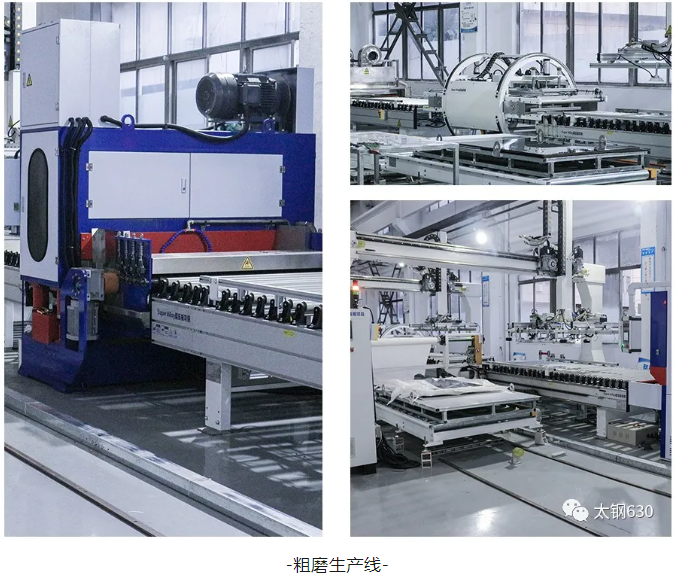

First of all, let us take a look at the rough grinding production line. We utilize advanced water grinding processes and equipment to effectively reduce the high temperatures, static electricity, and sparks generated during the grinding process. By precisely controlling the grinding parameters and process flow, we achieve the desired roughness and flatness of the steel plates. Our team of engineers has extensive experience and is capable of developing grinding solutions tailored to the specific needs of our customers, thus ensuring the stability and consistency of product quality.

The polishing and grinding production line further enhances the quality standards of our products. We utilize dry grinding processes along with specialized dust removal equipment, spray towers, and fans to extract dust. The dust is then wetted and settled in the spray towers to achieve effective dust removal. We also use grinding consumables with higher mesh counts and finer particles to improve the flatness and precision of the product surface. Through polishing, we are able to produce laminated steel plates with even higher precision, meeting the needs of customers with stringent requirements for roughness stability.

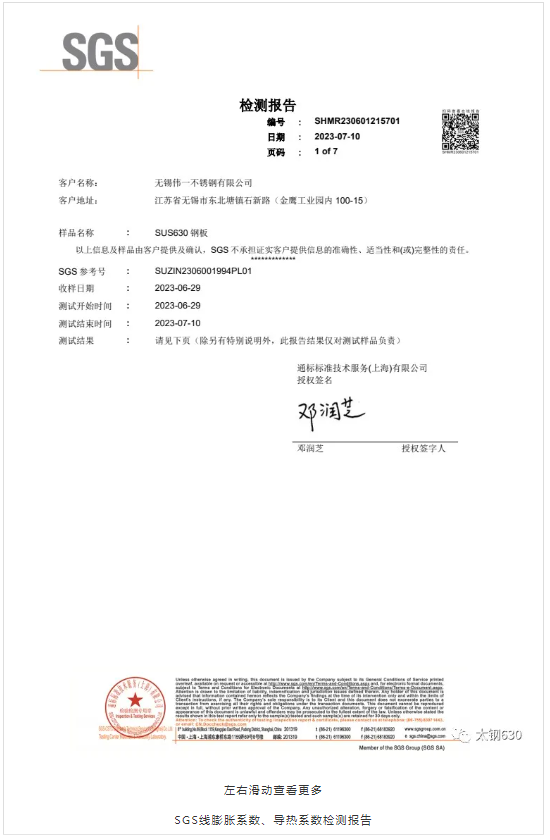

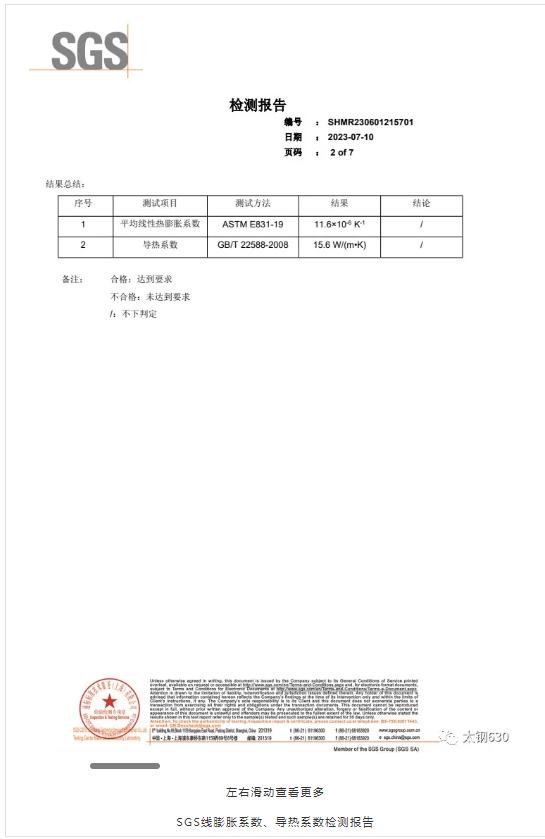

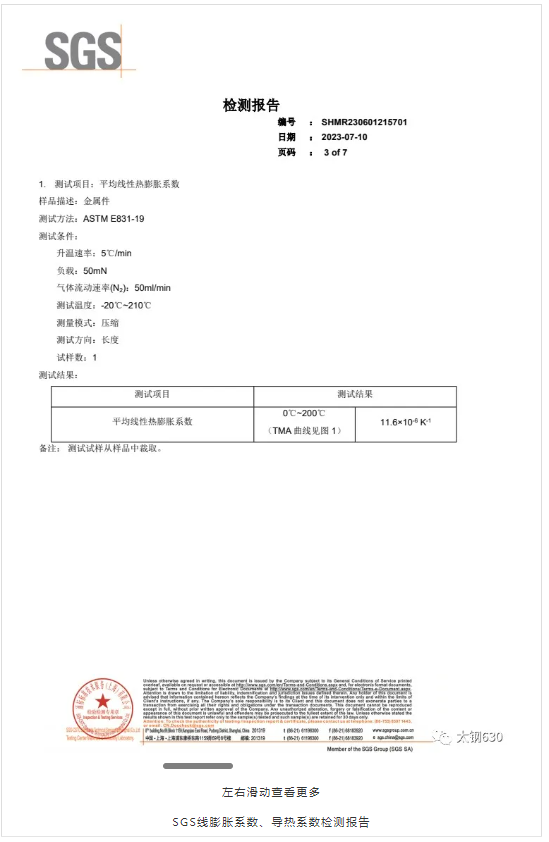

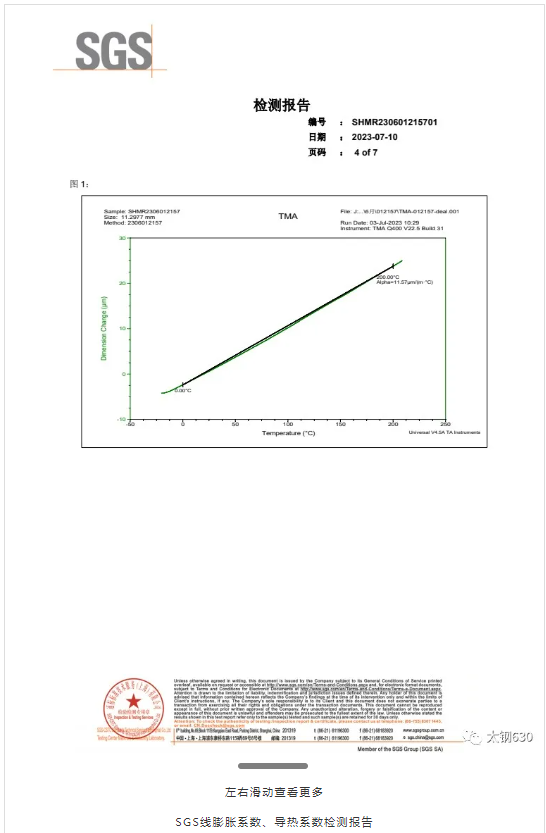

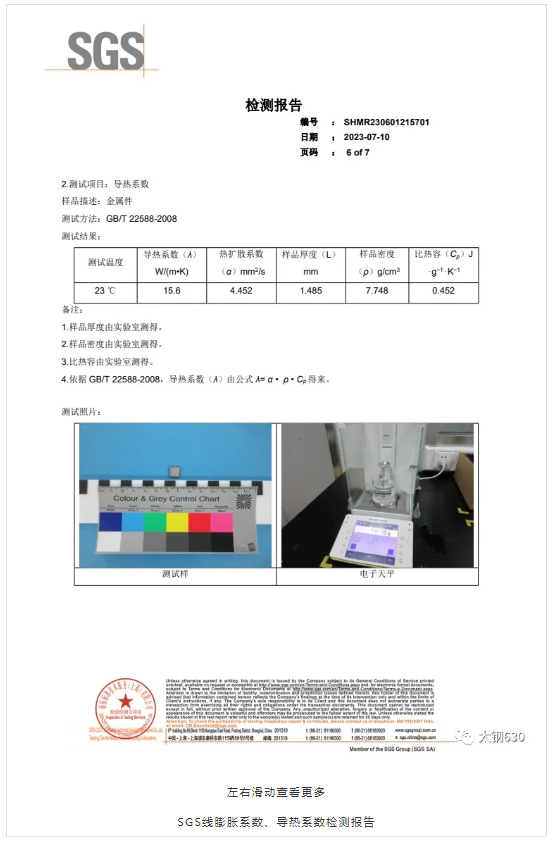

In addition to the rough grinding and polishing processes, we also place great emphasis on controlling the thermal expansion coefficient. During the grinding process, we use high-quality raw materials and strictly regulate the grinding temperature and duration to ensure that our products exhibit excellent thermal expansion properties. This is particularly important in many application areas, such as thermal management in the semiconductor and electronics industries.

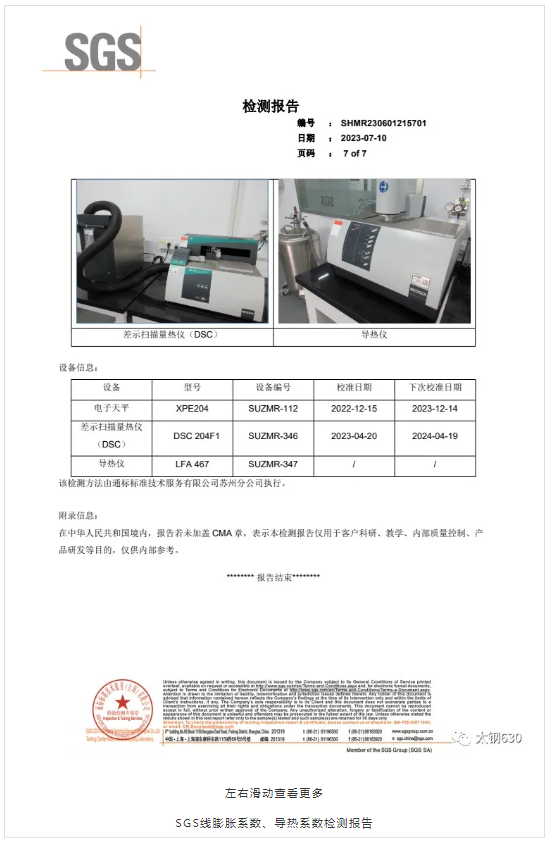

We are fully aware of the high demands for hardness, roughness, surface precision, and thermal expansion coefficient in laminated steel plates used for PCB and CCL grinding. Therefore, we conduct professional inspections of our products to ensure that they meet the requirements of our customers.

If you have any further questions or requirements regarding our grinding production lines or products, please do not hesitate to contact us. We look forward to working with you to provide you with high-quality pressed steel plate products and becoming your reliable partner.